Your print – our mission

Products

Polywest Sleeves

SOFTCOAT+ & SOFTCOAT PREMIUM

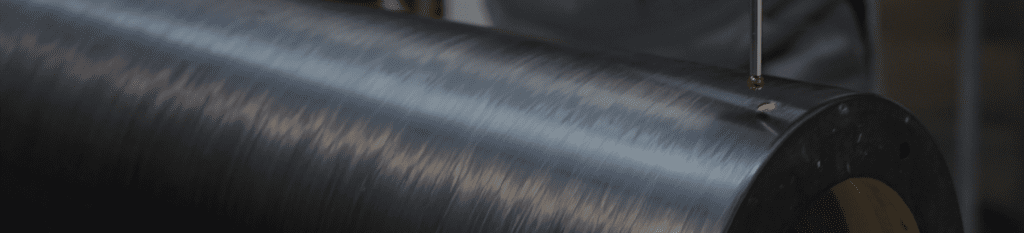

Polywest Sleeve Technology.

With an endless, seamless compressible surface for use without foam tapes in HD flexographic printing.

Compressibility and hardness of the softcoat surface can be adjusted on customer request.

Product features

Properties

- High-strength lightweight construction as standard for SOFTCOAT+

- Additional weight savings of up to 50 % with SOFTCOAT PREMIUM

- Optionally available with antistatic properties in conformity with 94/9/EG (= Atex 95)

- Available for all format ranges

Printing Quality

Barrier Layer – a progressive solution for long-term applications:

- Optimal dimensional stability

- High accuracy, especially in the area of parallelism and diameter

- Like every Polywest product, SOFTCOAT is equipped with a barrier layer

- Specific surface hardness adjustable to +/- 2 Shore A

Additional information

and technical data.

- SOFTCOAT+ & SOFTCOAT Premium data sheet

(english) (0.99MB)

Find your representative