At least since the opening of the in-house FlexoLAB a good five years ago, Lohmann has had a close cooperation with the company “Polywest” from Ahaus. The expert in plastics technology regularly supplies the graphic experts from Neuwied with the latest trends in sleeve systems. “The better the surface of the sleeve, the better our adhesive tape adheres to it. This in turn leads to excellent printing results,” explains Thomas Holzer, Market Manager Graphics at Lohmann. For this reason, he says, it is enormously important for the printing experts to continuously educate themselves and to keep an eye on the latest developments in sleeve technologies.

Therefore, Polywest’s offer to provide the Bonding Engineers with their latest sleeve came in handy. “The contact originally came about through Dortschy, our distributor in Germany. Dortschy also distributes Polywest products and so the idea to present the latest sleeve innovation at FlexoLAB was born,” explains Holzer.

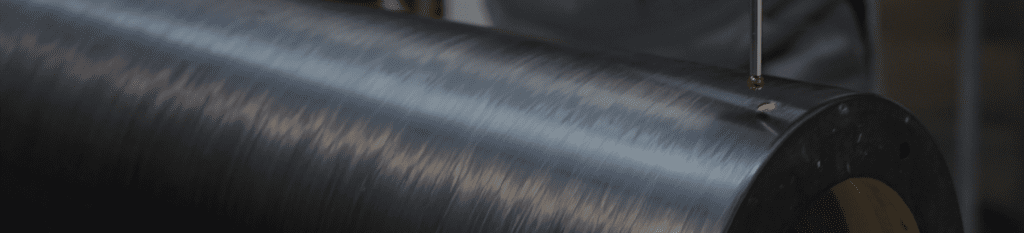

No sooner said than done, and the black sleeve with the sonorous name “Obsidian” landed in Neuwied. It has now been in operation for a good week and the colleagues are very satisfied. The new type of surface, which is extremely resistant to cuts and solvents, improves the bonding of Lohmann’s plate mounting tapes enormously. Its light weight and residue-free cleaning, as well as excellent concentricity, further facilitated its use. “As always, we are impressed by the outstanding sleeve quality and the uncomplicated cooperation with our partners,” summarizes Holzer.

He and his colleagues are certainly pleased with the latest member of their “sleeve family” at FlexoLAB.